When you’re diving into plumbing projects, understanding the different types of pipe fittings is essential for ensuring your system runs smoothly.

Whether you’re building, renovating, or simply doing maintenance work, the right pipe fittings can make all the difference. But with so many options available—from elbows to tees to couplings—it can be overwhelming to choose the right ones.

So, why does it matter?

Each fitting is designed for a specific purpose: to change the direction of the pipe, connect different pipe sizes, or seal off a section of the system. The right fit ensures there’s no leakage, no awkward twists in the pipes, and everything flows as it should.

And here’s the thing: if you don’t choose the right fitting for the job, you might find yourself dealing with leaks, inefficient systems, or costly repairs. That’s why understanding the different pipe fittings and their roles is key to confidently tackling any plumbing project.

At Excel Mechanical, we make it easy for homeowners and businesses to access the best plumbing solutions. Whether you’re working on a residential fix or handling a larger commercial project, we have the expertise to ensure your system is top-notch.

In this blog, you will learn:

- The materials used in plumbing pipe fittings and why they matter.

- The various types of pipe fittings and their unique functions.

- Key considerations to keep in mind when selecting the right fittings for your plumbing project.

Let’s get started!

Materials Used in Plumbing Pipe Fittings

Firstly, let’s take a look at the most common materials that are used in plumbing pipe fittings:

- Plastic: Plastic fittings are popular due to their durability and resistance to corrosion. They are lightweight, flexible, and budget-friendly, making them ideal for home and business use. Plastic fittings efficiently handle temperature changes and water pressure.

- Copper: Copper is a classic choice for plumbing. It resists heat and does not corrode easily. Copper fittings are often used in older homes for reliability and longevity.

- Steel and Stainless Steel: These materials are known for their strength and durability. Stainless steel is often chosen for its rust resistance. Steel fittings are common in both residential and commercial settings where high-pressure handling is necessary.

- Brass: Brass is used for its flexibility and resistance to rust. It’s excellent for fittings requiring precise water flow control, such as valves and hose bibs.

- PVC (Polyvinyl Chloride): PVC is often used for drain, waste, and vent systems. It’s cost-effective and easy to install, making it a popular choice for many plumbing projects.

From simple upgrades to complex installations, each material has its benefits.

Types of Pipe Fittings

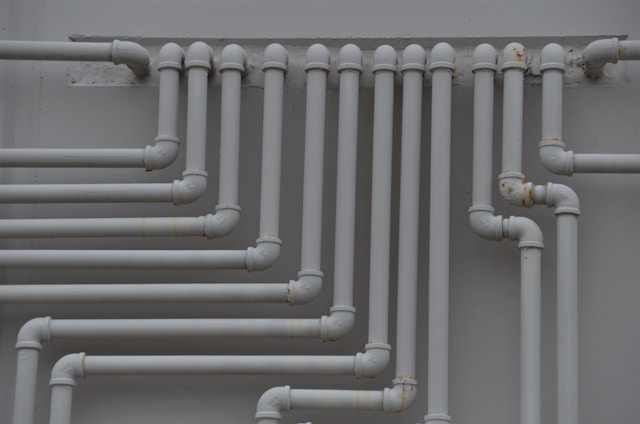

Pipe fittings are essential to connect pipes in plumbing systems, allowing them to change direction, branch off, or connect with different pipe sizes. Understanding the types and their functions can help you choose the right fittings for your plumbing projects.

Elbows

Elbows are fittings used to change the direction of a pipe.

They come in different angles, such as 45 and 90 degrees. Elbows can be threaded or welded in steel, copper, or PVC. The choice depends on the application and the type of pipe being used.

Elbows are crucial for routing pipes around obstacles, making them a versatile component in plumbing.

Tees

Tees are fittings that allow pipes to branch in three directions.

This T-shaped fitting has one inlet and two outlets at 90 degrees to the main line. Tees are commonly used in installations where fluid flow needs to be split or combined.

They are available in brass, copper, and plastic and can be used in various systems, such as water supply or gas pipelines.

Couplings and Unions

Couplings connect two pipes to prevent leakage.

They can be rigid or flexible, with threaded or socket ends. Unions are similar but allow easy disconnections for maintenance. Unions have three parts: a nut, a female end, and a male end.

Both join pipes of different sizes or materials, providing flexibility in plumbing installation and repair.

Adapters

Adapters are used to connect pipes of different types or sizes.

They have one threaded side and one plain end to connect different piping systems. Adapters can transition from male to female threads or from PVC to metal pipes.

Choosing the right adapter ensures a proper seal and reliable connection, accommodating various plumbing requirements.

Olets

Olets are branch fittings connecting smaller and larger pipes, typically with different diameters.

They provide an outlet by welding or threading into a larger pipe. Olets are used in high-pressure systems where space and weight are considerations.

They come in forms like weldolets, sockolets, and thredolets, each designed for specific connection points in plumbing.

Caps and Plugs

Caps and plugs are used to close the end of a pipe.

Caps fit over the end of a pipe, while plugs fit inside. These fittings are essential for protecting pipe ends during construction or maintaining a seal when part of the system is not in use.

They are typically threaded or socketed, available in various materials for different applications.

Valves

Valves regulate, direct, or control the flow of liquids or gases through a system. Common types include gate valves, ball valves, and check valves.

Each type serves a specific function: on/off control or preventing backflow. Choosing the right valve depends on the application, pressure requirements, and type of fluid being controlled.

Nipples

Nipples are short pieces of pipe with threads at both ends. They are used to join two fittings or pipes. Nipples vary in length and material, such as steel or brass.

They are essential for connecting different piping components or extending pipe runs, offering versatility in plumbing configurations.

Function and Application of Pipe Fittings

Pipe fittings are essential components in plumbing systems. They help connect different pipe sections, allowing water or gas to flow efficiently.

The main functions include connecting, changing direction, reducing size, and closing off pipes. Each function is critical for ensuring the system operates correctly and meets specific design requirements.

Different types of fittings serve different purposes.

- Elbows, which come in 90-degree and 45-degree angles, are used for changing direction.

- Tee fittings help divide or combine flow.

- Reducers allow the connection of pipes with different diameters.

- Caps and plugs are used to close pipes securely.

The application of these fittings varies. In residential plumbing, fittings must handle daily water use and meet safety standards. In commercial settings, fittings often need to support higher pressure and larger volumes. Both scenarios require durable materials that resist wear.

Fitting Connection Types

Different types of plumbing pipe fittings are key to ensuring a strong and lasting connection in your plumbing system. This guide explores how these fittings are attached and used to create reliable connections that suit various needs.

Threaded Fittings

Threaded fittings use threads—spiral grooves often found on the inner and outer surfaces of pipes and fittings—to attach two pieces securely. They are commonly used in plumbing systems to join metal pipes. You simply screw the male and female ends together.

These fittings are beneficial because they are easy to install and can be dismantled, making repairs simple. They are especially suited for applications where high pressure is a factor. To prevent leaks, sealant tape or compound must be applied.

Soldered or Sweat Fittings

Soldered or sweat fittings join copper pipes by melting a filler metal using hea.

This process creates a watertight seal. Due to their strong and permanent connections, these fittings are often found in residential plumbing systems.

They require a torch and solder wire for installation, which means they involve a more complex setup than some other fittings. The fitting must be heated appropriately for the metal to flow and create a solder joint, ensuring durability under various temperatures.

Compression Fittings

Compression fittings are used to connect pipes by compressing a nut and sleeve onto a pipe.

This creates a tight seal without using soldering or threading. They are beneficial when pipes need to be disconnected frequently or adjusted.

The installation is simple. You position the pipe into the fitting and tighten the nut, compressing the sleeve against the pipe, ensuring a leak-free connection. While easy to install, they might not be the best for high-pressure applications.

Push-fit or Push-to-connect Fittings

Push-fit fittings, also known as push-to-connect, are user-friendly and require no tools for installation.

You simply push the pipe into the fitting, and it locks in place with a watertight seal. These fittings are excellent for quick repairs and installations.

Their simplicity makes them ideal for DIY projects or situations where time concerns them. However, they are primarily used with specific pipe materials, such as copper, CPVC, or PEX.

Mechanical Sleeve or Slip Fittings

Mechanical sleeve or slip fittings connect pipes by a sleeve that slips over the ends.

They rely on compression or gaskets to create a seal between pipes, offering a secure connection. These fittings are valuable when pipe expansion or contraction due to temperature changes is needed.

Installation involves positioning the sleeve over the pipe ends and tightening it, usually with a wrench. The sleeve’s design allows for flexibility and movement without compromising the seal.

Flared Fittings

Flared fittings are commonly used in gas and high-pressure fluid applications.

They involve flaring the pipe end with a special tool, then using a nut to secure it to the fitting. This method ensures a robust seal that can withstand extreme conditions.

You need specific tools to create and secure the flare, but once completed, it provides a reliable and durable connection. This makes them ideal for high-stress environments like HVAC systems.

Crimped or Press Fittings

Crimped or press fittings work by deforming the fitting onto the pipe with a pressing tool to create a sealed connection. These fittings ensure secure, mechanical joints in metal or PEX pipes.

The installation is efficient. A pressing tool is required to crimp the fitting onto the pipe, providing a quick and reliable connection. The fittings can handle various pressures, making them suitable for residential and commercial applications.

Standards and Specifications for Pipe Fittings

When dealing with pipe fittings, consider various standards and specifications. These guidelines ensure your plumbing systems are safe, reliable, and efficient.

Common Standards

Here are some common standards for pipe fittings:

- ASME (American Society of Mechanical Engineers): Focuses on mechanical properties and pressure ratings.

- ASTM (American Society for Testing and Materials): Provides material standards.

- ANSI (American National Standards Institute): Ensures consistency across different products.

Pipe Fitting Materials

Pipe fittings are made of materials such as PVC, copper, brass, and stainless steel. Each has its own specifications, which affect their use in various environments and applications.

Pipe Sizing

Proper sizing follows standards to ensure system efficiency. This involves considering pipe diameter and thickness based on pressure and temperature requirements.

Threading and Joining

Threading specifications require adherence to standards such as NPT (National Pipe Thread), which guarantee a secure and leak-proof connection.

Consulting experts at Excel Mechanical ensures your systems meet all relevant standards for any plumbing project. Our team provides tailored solutions, delivering exceptional quality for residential and commercial needs.

Selection Criteria for Pipe Fittings

Choosing the right pipe fittings for your plumbing project is crucial for success. Factors like material, size, and application play a key role.

Material

- Plastic: Lightweight and resistant to corrosion. Ideal for many residential uses.

- Metal: Durable and suitable for high-pressure applications. Offers longevity in both residential and commercial settings.

Size and Compatibility

Ensure fittings match the size of your pipes and check for compatibility with the pipe material to avoid issues down the line.

Application

- Indoor Plumbing: Choose fittings that suit household water systems.

- Outdoor Use: Opt for materials that can withstand weather conditions.

Pressure and Temperature

Fittings must handle the pressure and temperature they will be exposed to. Select fittings rated for the appropriate conditions.

Cost Efficiency

Consider both the initial cost and long-term durability. While some fittings may be cheaper upfront, long-term repair costs might outweigh initial savings.

Installation Considerations for Pipe Fittings

When installing pipe fittings, consider the material.

- Common materials include PVC, copper, and PEX, each suited for specific applications. Ensure compatibility to prevent leaks and other issues. Ensure that some materials expand or contract with temperature changes, affecting the seal’s effectiveness. Understanding the climate and the system’s heat thresholds can prevent future headaches.

- Pressure ratings are another aspect. Ensure your fittings can handle the water or gas pressure in the system. Overpressure can cause fittings to crack or fail, leading to costly repairs.

- Proper alignment is necessary to ensure a strong, secure connection. Misalignment can lead to leaks or breaks, so use appropriate tools like wrenches and alignment guides.

- Sealants and adhesives help secure the joints. Using the right product ensures a watertight connection. Be mindful of the curing time for sealants to avoid leaking.

- Finally, accessibility should be considered. Ensure fittings are placed in easily accessible areas for maintenance and repairs. This reduces the time and cost involved when working on the system.

Trust our team to evaluate and meet your HVAC and plumbing needs. Our experts provide optimal solutions that fit your budget and ensure long-lasting performance.

Maintenance and Repair of Pipe Fittings

Maintaining pipe fittings is essential to prevent leaks and other problems. Regular inspection helps spot issues like corrosion or cracks early. Doing this can save you from costly repairs later.

Common Issues:

- Leaks: Often caused by worn-out seals or loose connections.

- Corrosion: May occur in metal pipes, leading to weak points.

- Blockages: Accumulated debris can block flow.

Repair Tips:

- Tighten Loose Fittings: Use a wrench to secure them properly.

- Replace Damaged Parts: Swap out any cracked or corroded fittings.

- Clear Blockages: Use tools like a plunger or plumbing snake.

Using the right tools is crucial for effective repair work. A pipe wrench, plunger, and sealant are essential. Always ensure fittings are compatible with your pipes to avoid further issues.

Advancements in Pipe Fitting Technology

Pipe fitting technology has advanced greatly, making systems more efficient and reliable.

- Smart fittings are now part of modern plumbing. These use sensors to monitor water flow and detect leaks in real time. Installing these can reduce water waste and help catch problems early.

- Another breakthrough is push-fit technology. This allows you to connect pipes quickly without special tools. These fittings ensure a strong seal, which saves time and effort during repairs or installations.

- Materials have also evolved. Newer, more durable materials like PEX and PVC make pipes last longer and resist corrosion. This change lowers maintenance costs and extends the life of plumbing systems.

- 3D printing technology is also making waves. It allows for custom fittings that meet specific requirements. This can be especially helpful in unique or complex plumbing systems.

- Moreover, digital modeling and simulation tools are becoming essential. These tools help design more efficient systems and foresee potential issues before they happen, improving planning and execution.

By choosing Excel Mechanical, you ensure expert installation and maintenance. Our focus on quality and value guarantees that your plumbing system will meet your needs effectively and economically.

Frequently Asked Questions

When it comes to plumbing pipe fittings, knowing the ins and outs can help you make informed decisions. But, sometimes, a few questions pop up along the way. Don’t worry, we’ve got you covered with answers to some common plumbing pipe fitting questions!

What are the various classifications of plumbing pipe fittings?

Plumbing pipe fittings are classified based on their purpose, such as elbows for changing direction, tees for joining pipes, and reducers for altering pipe size. Each classification serves a specific function in the plumbing system.

How do different types of plumbing couplings vary in their application?

Couplings connect two pipes to maintain the continuity of the plumbing line. Some are rigid for permanent connections, while slip couplings allow for repair work without cutting the pipes.

Can you list the common materials used for pipe fittings in plumbing?

Common materials include PVC, copper, brass, and stainless steel. PVC is lightweight and cost-effective, while copper and brass provide durability. Stainless steel is chosen for its corrosion resistance.

What are the primary considerations when selecting pipe fittings for a plumbing project?

Considerations include the type of fluid being transported, temperature, pressure levels, and compatibility with the existing pipes. These factors ensure the fitting’s longevity and performance.

How do pipe fitting dimensions influence installation and compatibility?

Correct dimensions are crucial for a seamless fit between fittings and pipes. Mismatched sizes can lead to leaks and compromise the system’s efficiency.

What role do pipe fittings play in the overall integrity of a plumbing system?

Fittings join different sections of pipes, enabling fluid flow while preventing leaks. They contribute significantly to the system’s durability and reliability, ensuring smooth operation.