Choosing the right company for gas line installation and repair is crucial for safety and efficiency. At Excel Mechanical, you can trust our expert team to ensure that your gas lines are installed and maintained correctly. We offer solutions tailored to your needs and budget, ensuring great value for your investment.

Whether it’s your home or business, a properly installed gas line is important for safety. Quality installations help prevent leaks and other hazards. Our skilled technicians at Excel Mechanical are dedicated to delivering exceptional quality in every job. We prioritize your safety and work with precision and care.

When it comes to HVAC and plumbing services, Excel Mechanical stands out for our commitment to excellence. We design systems that fit your specific requirements, making us a dependable choice for both residential and commercial projects. With us, you can expect outstanding service and a focus on meeting your needs effectively.

Understanding Gas Line Installation and Quality Standards

When installing gas lines, safety and quality are crucial. Proper installation ensures that gas systems function efficiently and safely. Attention to detail, adherence to codes, and expert handling are key.

Key Components:

- Pipes: Choose high-quality materials like copper or steel for durability.

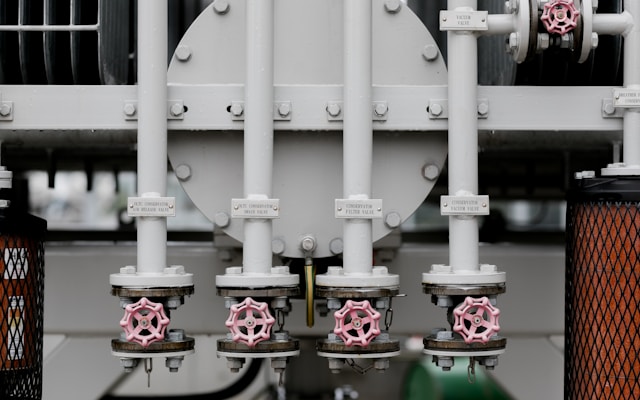

- Valves: Ensure that shut-off valves are accessible and secure.

- Regulators: Maintain consistent gas pressure to prevent leaks.

Installation Steps:

- Planning: Assess the property to determine the correct placement of gas lines.

- Material Selection: Select materials that suit the environment and usage.

- Installation: Lay out and connect pipes with precision.

Quality Standards:

- Meet local and national codes.

- Perform pressure testing for leaks.

- Ensure all connections are secure and sealed.

Why Choose Us?

At Excel Mechanical, expert installation is guaranteed. Our team uses the best techniques, ensuring reliability and efficiency. We provide tailored solutions to meet your specific needs and budget, making us a top choice for any gas line, HVAC, or plumbing service.

We emphasize safety and performance. Your peace of mind is important, and with Excel Mechanical, you get both quality installations and great value, ensuring a safe and efficient gas system for your home or business.

Selecting Professional Gas Line Services

Choosing professional gas line services is critical for ensuring safety and efficiency. Focus on certifications, experience, insurance, and reputation when making your choice.

Certifications and Training

When selecting a gas line service, it’s essential to verify their certifications and training. Certified technicians have undergone specific educational programs that prepare them for handling gas lines safely. Training often includes both classroom learning and on-the-job experience, covering topics like pipe installation and leak detection. Look for industry-recognized certifications like those from the National Gas Association.

Ensuring technicians are well-trained provides peace of mind and guarantees compliance with local building codes. A certified team like Excel Mechanical follows best practices and adapts to new technological advancements, ensuring safe and efficient service.

Experience and Reputation

Experience and reputation are crucial when hiring gas line services. An experienced provider has likely handled various challenges, making them better equipped to manage unexpected issues efficiently. Check online reviews and ask for references to verify a company’s reputation. Positive feedback often indicates reliability and quality of service.

Excel Mechanical builds trust through years of successful HVAC and plumbing services, both residential and commercial. Known for exceptional quality and great value, we tailor systems to meet your specific needs and budget, ensuring long-term satisfaction.

Insurance and Licensing Requirements

Ensure the service provider has proper insurance and licensing. Licensing verifies the company meets industry standards, while insurance protects you from potential liabilities or damages. A fully licensed and insured company safeguards against legal complications.

Request proof of insurance and verify their licensing status with local authorities. Confirming these details helps avoid costly mistakes and ensures proper compliance. Reliable companies like Excel Mechanical take these responsibilities seriously, offering transparency and peace of mind.

Pre-Installation Considerations

Before installing a gas line, it’s vital to choose the right materials, follow essential safety protocols, and understand local regulations. These steps ensure the safety and efficiency of your gas system.

Gas Line Material Options

Choosing the suitable gas line material is crucial for safety and efficiency. There are several options available, each with its benefits and drawbacks. Copper is durable and resistant to corrosion, making it a good option for many applications. Steel offers strength but can rust over time without proper treatment. On the other hand, flexible gas pipes, like CSST, are easy to install in tight spaces and resistant to gas leaks. However, they can be more expensive than traditional materials. Consider your specific needs and budget when selecting a material. Consulting with professionals, like those at Excel Mechanical, can help make the right choice for your project.

Safety Protocols and Inspections

Gas line installation and repair require strict attention to safety. Following established safety protocols can prevent accidents and gas leaks. Before beginning, ensure that the area is well-ventilated. Regular inspections by licensed professionals are essential to detect any issues early. During installation, use proper protective gear and tools. Conduct pressure tests to confirm the system’s integrity. Hiring experts from companies like Excel Mechanical ensures a high standard of safety, as our team stays up-to-date with the latest practices to provide reliable services. We prioritize exceptional quality while keeping your budget in mind, providing you with the best possible solutions for your needs.

Local Codes and Regulations

Adhering to local codes and regulations is mandatory. Different regions have specific requirements for gas line installations. Permits may be needed before starting work. Understanding these rules helps avoid fines and ensures the safety of your property. Research or consult local authorities to understand the necessary permits and regulations in your area. Failure to comply can lead to significant setbacks. Professionals in the field are familiar with these requirements and can guide you through the process. Seek advice from experienced installers to ensure everything is done according to local laws, ensuring a smooth installation process.

The Installation Process

Installing gas lines involves precise planning, careful execution, and thorough testing to ensure safety and efficiency. The main steps include planning, trenching, piping, and connection. Each step is vital to a successful installation.

Planning and Layout

Before installation, a detailed plan is essential. This plan identifies where the gas lines will run and includes a map of existing utilities. The plan needs to account for safety distances from other structures and utilities.

Information Checklist:

- Gas Line Route: Determine the path avoiding obstacles.

- Regulations: Ensure compliance with local codes and safety standards.

- Materials and Tools: Gather necessary supplies.

Creating a precise layout ensures that the installation is efficient and safe. Planning helps in choosing the best materials and methods for your needs.

Trenching and Piping

Once planning is complete, trenching begins. This involves digging trenches where the gas line will be laid. Trenching requires accuracy to avoid existing underground utilities.

Trenching Steps:

- Mark Utilities: Use accurate markings for existing lines.

- Dig Trenches: Follow the planned layout.

When the trench is prepared, piping is placed into the trench. Pipes should be correctly sized for the gas flow and securely joined. Ensuring proper depth and support for the pipes is crucial for long-term safety.

Connection and Testing

Connecting the gas line involves joining the pipe sections and integrating them into the building’s gas system. It’s important to ensure a secure and leak-free connection.

Testing Steps:

- Pressure Test: Check for leaks by applying pressure.

- Inspection: Have a professional assess the work.

Testing the system is critical to confirm the installation’s integrity and safety. At Excel Mechanical, our skilled professionals ensure that each connection meets high safety standards. With our expertise, you get a reliable system tailored to suit your needs and budget, showcasing our exceptional quality and great value for both residential and commercial services.

Common Issues and Troubleshooting

When it comes to gas line installation and repair, there are a few common problems that you may encounter. These include detecting leaks and corrosion, pressure issues, and ensuring your appliances are compatible with your gas system. Each of these problems can affect the safety and efficiency of your gas setup.

Leaks and Corrosion Detection

Gas leaks can be dangerous. To spot them, check for a rotten egg smell, which is a clear sign. Additionally, listen for hissing sounds near the gas lines. Use soapy water on connections to identify leaks; bubbles will form if there’s a leak. Corrosion can weaken pipes over time. Inspect pipes regularly for rust or discoloration, especially where moisture is present. Staying on top of routine maintenance will help prevent these issues. Calling in a professional service, like Excel Mechanical, ensures a thorough inspection and reliable fixes for any detected issues.

Pressure Problems

Pressure issues can cause appliances to work poorly or even stop working. Check your gas pressure regularly with a simple pressure gauge. Low pressure might mean a blockage, which often occurs in narrow pipes. High pressure could cause a dangerous build-up. Ensure that regulators and valves are in good working order. Adjusting pressure should be left to professionals to avoid any risks. At Excel Mechanical, experienced technicians can assess and adjust gas pressure systems with great accuracy and safety.

Appliance Compatibility

Matching your appliances with the right gas line setup is crucial. Ensure that the appliances are designed for the type of gas supply you have, whether natural gas or propane. Check the manufacturer’s manuals for information on gas pressure requirements or converter kits if you aren’t sure. Make necessary adjustments to avoid inefficient operation or damage. Having the right components and settings ensures your appliances run smoothly and safely. Consulting with experts ensures your setup meets your needs effectively. Excel Mechanical offers customized gas services tailored to your specific home or business requirements.

Repair Procedures

Gas line repairs should be handled with great care to ensure safety and reliability. This process involves identifying issues, applying proper repair methods, and ensuring the repair works effectively, maintaining safety for all.

Assessment and Diagnosis

Accurate assessment is the first step in gas line repair. You should inspect the area for any signs of damage or leaks, such as hissing sounds or the smell of gas.

Tools you might need:

- Gas leak detector

- Wrench

- Soap solution

Using a gas leak detector is vital to pinpoint leak locations. Visual inspection is important to check for corrosion, dents, or loose fittings.

Safety Tip: Always turn off the gas supply before any inspection or repair work begins.

Proper identification of the problem helps in planning the repair process effectively.

Repair Techniques

Once the issue is found, the right repair methods must be applied. Small leaks may require tightening of connections or using sealants.

For more significant damage, you might need to replace sections of the pipe.

Common materials:

- Pipe sealant

- Replacement pipes

Ensure fittings and pipes are compatible with your gas type and pressure. Regular hand tools like wrenches can help with tightening, but specialized tools may be necessary for specific repairs.

It’s important to follow manufacturer guidelines to maintain safety and compliance.

Validation and Follow-Up

After repairs, you should check that everything works correctly. This involves turning the gas back on and testing for leaks again.

Steps:

- Turn on the gas supply.

- Use a leak detector or soap solution to check for leaks.

- Reinspect the area to ensure stability and integrity.

Document the repairs for future reference. It helps to contact professionals like Excel Mechanical for assurance. Our dedication to quality ensures reliable and economical solutions tailored to your needs.

Excel Mechanical is a trusted choice for both residential and commercial gas line services, offering exceptional quality and value.

Maintaining Your Gas Line System

Gas lines are vital for your home or business. They need proper upkeep to ensure safety and efficiency. This section explores how routine inspections, knowing how to handle emergencies, and making smart upgrades will keep your gas line system in top shape.

Routine Inspections

Regular checks of your gas lines are essential. Look for signs of wear like rust or corrosion. Listen for hissing sounds, which might indicate a leak. Smell for gas odors, especially near connections.

Hiring professionals from Excel Mechanical ensures thorough inspections. We use advanced tools to detect issues early. Regular inspections help prevent costly repairs and keep your system efficient. Schedule them annually to maintain a safe and functional gas line system.

Emergency Response

Knowing how to act in a gas emergency is crucial. If you suspect a leak, evacuate the area immediately. Avoid using electrical devices or open flames. Move to a safe location and call emergency services.

Make sure you have the contact information of experts like Excel Mechanical handy for urgent repairs. Our team responds quickly to restore safety. Regular safety drills at your home or workplace can also prepare everyone for a real incident. Being ready ensures swift action and minimizes damage.

Upgrades and Enhancements

Enhancing your gas line system can improve safety and efficiency. Consider upgrading to modern materials like flexible gas pipes. These are more resistant to leaks and natural movements.

Smart gas detectors connected to your phone offer instant alerts. Excel Mechanical offers tailored solutions that fit your needs and budget. Upgrading not only keeps your system current but also maximizes its lifespan, ensuring reliable service for years to come.

Environmental Considerations and Sustainability

When installing or repairing gas lines, it’s important to think about the environment. Using efficient materials can help save energy and reduce waste. Energy-efficient systems not only benefit the planet but also help you save on utility bills.

Proper gas line installation can minimize leaks, which lowers harmful emissions. Regular maintenance checks are essential for reducing this risk. Choose materials that are long-lasting and eco-friendly to make a positive impact.

At Excel Mechanical, we make sure your needs and budget are met. Projects are designed with sustainability in mind. It’s important for both you and the environment. Trust our expertise for the best HVAC and plumbing services. If you want exceptional quality and value, you’re in the right hands.

Benefits of Sustainable Practices:

- Reduced Energy Consumption: Lower your carbon footprint with efficient systems.

- Cost Savings: Save money in the long run through energy-efficient installations.

- Safety: Reduce risks of leaks, protecting both your home and the environment.

Choosing eco-friendly options can lead to better air quality and a healthier home. Excel Mechanical tailors its services to fit your specific needs, providing quality results. Trust us to help make your gas system more sustainable.

End-of-Life Disposal and Recycling Options

Proper disposal of old gas lines is important for safety and the environment. Start by checking local regulations since rules can vary. Some areas offer recycling programs for metal pipes, and you may need to arrange for a specialized disposal service for hazardous materials.

Here’s a simple process to follow:

- Shut Off Gas: Ensure the gas is turned off completely.

- Detach: Carefully disconnect the old gas lines.

- Sort Materials: Separate metal parts for recycling.

Why Choose Excel Mechanical?

For professional gas line services, Excel Mechanical is your best choice. We offer top-quality HVAC and plumbing solutions, ensuring you get the best system for your home or business.

Recycling metals from old gas lines reduces waste. Many community recycling centers accept these materials. Check with local facilities to understand what is accepted and any requirements.

If you’re handling commercial projects, contact a waste management company specializing in industrial disposal. They can safely recycle or dispose of larger quantities or complex materials.

Working with professionals like Excel Mechanical ensures exceptional quality service. Our team is trained to handle gas line installations and ensure the materials are properly disposed of. This way, you stay compliant while protecting the environment and your community.

Frequently Asked Questions

Gas line installations and repairs involve several factors such as costs, qualifications, and repair responsibilities. Familiarity with signs of necessary repairs and choosing a reliable company are important to ensure safety and efficiency.

How much does it typically cost to install a new gas line?

The cost usually depends on the length of the line and the complexity of the installation. Pricing can range from a few hundred to a couple of thousand dollars. Contact your installer for a precise estimate tailored to your specific needs.

What qualifications should a professional have for installing or repairing gas lines?

Professionals need to be licensed and experienced in handling gas systems. It’s important they are trained in safety standards and familiar with local building codes. This ensures the job is done safely and correctly.

Who is generally responsible for the repair of a gas line?

Property owners are typically responsible for gas line repairs that are located on their property. Always check your insurance and utility agreement for specific details about who holds responsibility in your area.

What are common signs that a gas line needs repair or replacement?

You might notice strange odors, hissing sounds, or dead vegetation near the line. Higher gas bills can also be a signal. If you suspect a leak, it’s crucial to contact a professional immediately.

How do I choose a reputable company for gas line installation or repair?

Look for companies with good reviews, proper licensing, and experience in the field. Excel Mechanical offers exceptional quality and value for all your HVAC and plumbing needs. We ensure each system meets your personal and financial requirements.

What is the estimated time frame for professional gas line installation?

The time frame for gas line installation varies based on complexity and length. It usually takes a few hours to a couple of days. At Excel Mechanical, we prioritize efficiency and quality to get your system running as soon as possible.